3D Scanning a C4 Corvette: The First Step in a Custom Build

Published by Tyler M. on Feb 25th 2025

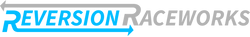

Have you ever wondered what it takes to 3D scan an entire car? Well, today, we’re diving into the process of scanning a C4 Corvette—step one in an exciting custom design project. This isn’t just any quick scan; it’s the foundation for a long-term transformation, with crazy body panel designs and custom CAD work.

Why 3D Scan the Corvette?

Before we start cutting, modifying, or adding new elements, we need a precise digital model of the car. A 3D scan allows us to design and test everything virtually, ensuring accuracy before making physical changes. This saves time, effort, and avoids costly mistakes.

We’re also teaming up with Andres Wennevold, whose work in 3D design is incredible. By combining ideas and expertise, we can take this project to the next level.

Preparation: The Key to a Successful Scan

Like any project, preparation is crucial. Before scanning, we covered the Corvette with different types of markers:

-

AESUBdots Retro Infinity Markers: Clear tape strips that allow for quick and widespread marker placement.

-

AESUBdots Retro Reflective Easy Removeable: Traditional 3D scanning markers used to fill in gaps and smaller sections.

-

Masking Tape on the Windshield: Helps simulate a solid surface for better scanning results. We also used AESUB Retro Reflective markers on the tape.

-

Masking tape with markers on the ground: Placed around the car to assist with scanning tricky areas like under the rocker panels and bumpers.

The Scanning Process

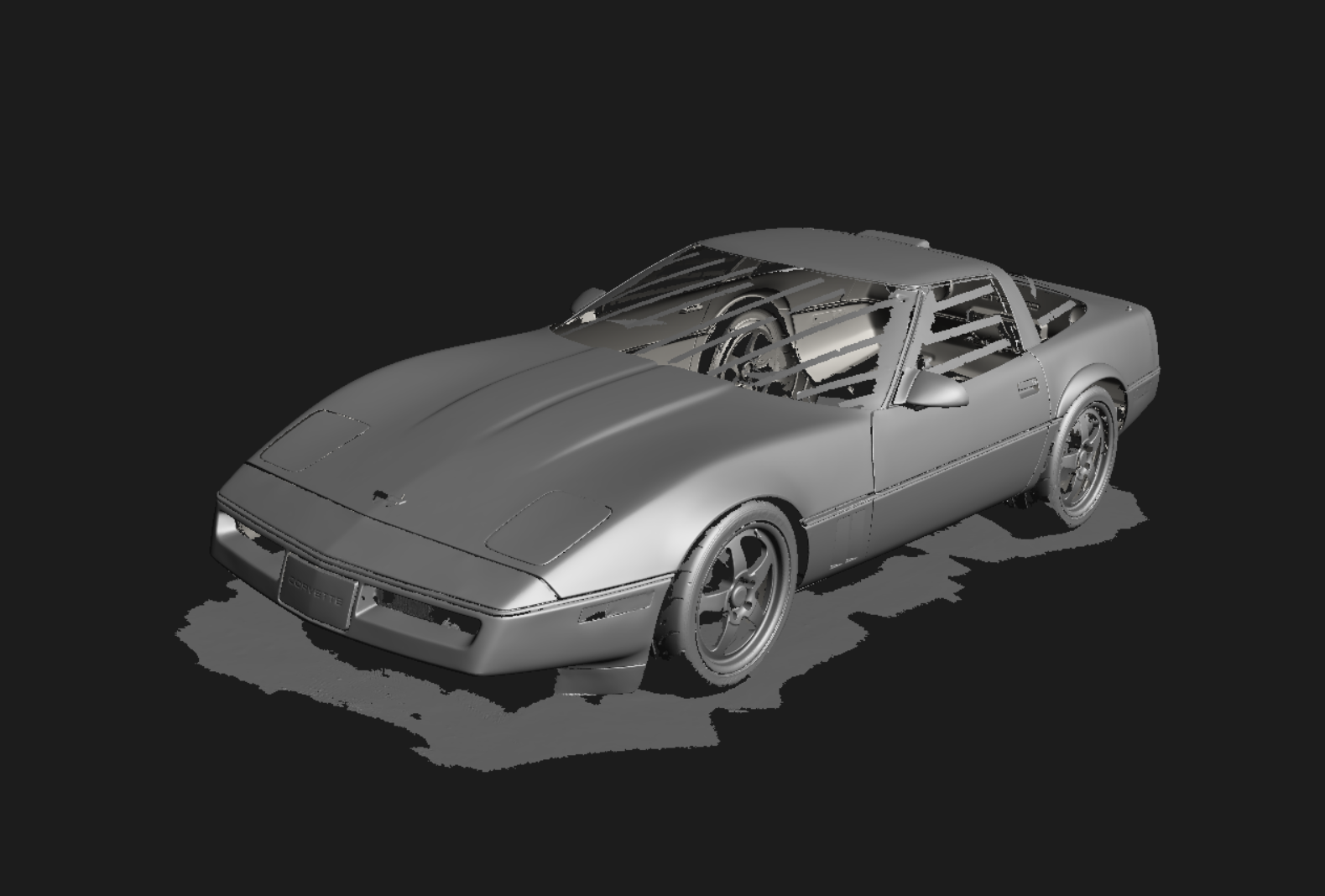

Once the car was prepped, we started with a marker-only scan. This serves as a reference framework, preventing errors and ensuring smooth alignment for subsequent scans. The best technique is to begin in the middle of the roof and expand outward like a spider web. This approach minimizes tolerance stack-up and enhances accuracy.

After setting up the Peel 3D scanner software, we imported the target scan, selected the right parameters, and started acquiring detailed data. One of the biggest challenges was scanning shiny and black surfaces, which often require a fine layer of scanning spray for better readability. The Corvette’s wheels, with their combination of dark and reflective surfaces, were particularly tricky, but a light spray made a huge difference.

Optimizing the Process

A key factor in making this process efficient was using a high-performance laptop. This significantly improved scan speed and recognition of colors and textures, showcasing the full potential of the Peel scanner.

With a clean, continuous scan, we had minimal gaps—proof of how well the technology works. The level of detail was impressive, capturing even the lettering on the tires.

Post-Processing & Alignment

Once the scan was complete, we moved into post-processing to refine the digital model:

-

Removing Isolated Patches: The Peel software automatically removes unnecessary noise and markers.

-

Data Selection Tools: Different tools like freeform, lasso, and connected selections helped in cleaning up unwanted elements.

-

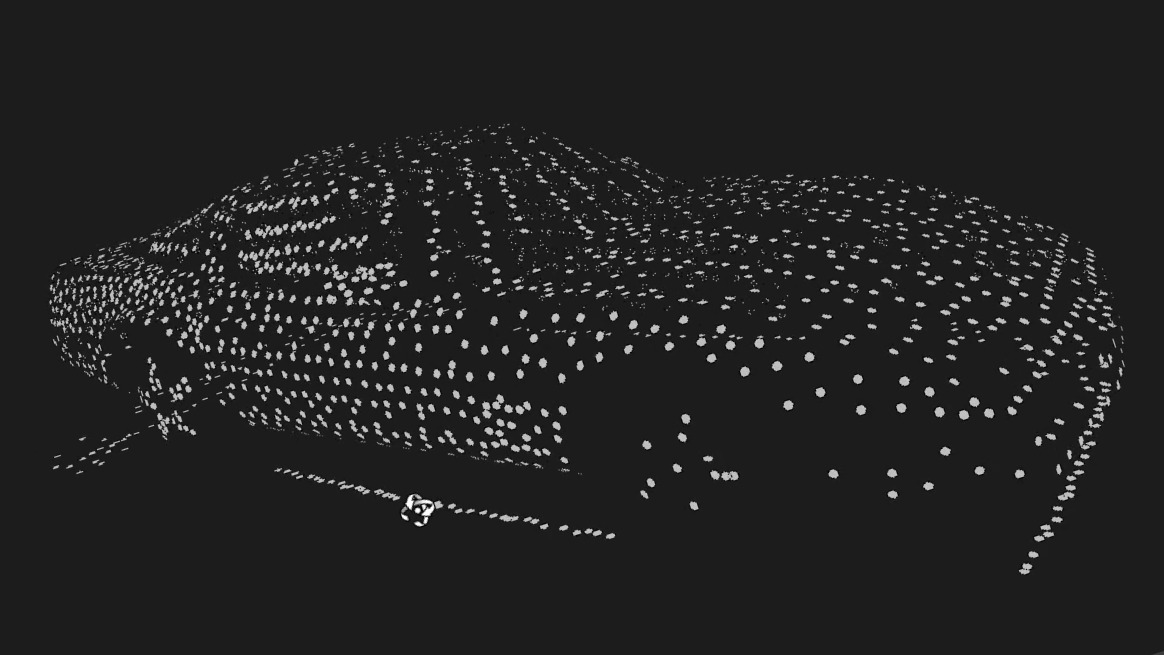

Aligning the Scan: Since scans exist in “floating” digital space, we needed to define a coordinate system. Using the floor as a reference for the XY plane, the rear bumper for the XZ plane, and the door for the YZ plane, we created a stable alignment that makes the scan easy to work with in CAD.

What’s Next?

With the scan finalized, the next step is importing it into SolidWorks for detailed design work. This is where we’ll start modeling the new body panels and modifications before making any physical changes to the car.

While the Corvette isn’t our main focus at the moment (the Suburban project is still in progress), this is just the beginning of what promises to be an exciting build. Stay tuned for more updates as we bring this digital transformation to life!

Want to see more of this process? Check out our Youtube video below! Feel free to contact us with any questions or inquiries you may have.